Decades ago, the manufacturing industry had to rely on active human labor, effort-extensive steps, and unnecessarily long production periods. However, the manufacturing industry has significantly improved with today’s current technology.

And one of those innovations is computer numerical control or CNC machining. Large production businesses and manufacturers often invest in having their CNC machines. However, more and more business owners are now recognizing the benefits of using a CNC machining service.

If you want to know more about CNC machining, continue reading as we discuss it and its basic concepts in this article.

What Is CNC Machining?

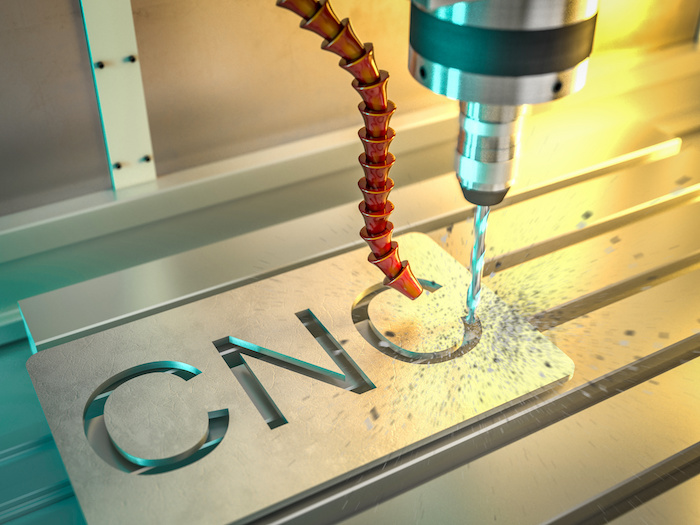

CNC machining is a manufacturing method where written code controls the machinery and tools. The code contains the entire machining process from start to finish, and the machinery follows the same set of instructions repeatedly, producing consistently accurate parts.

In more technical terms, machining is a type of subtractive manufacturing, which means that the material gets removed during the process. A CNC machine uses fast-moving cutters starting with a block material to quickly carve and cut away materials to create a finished part.

4 Primary Types Of CNC Machines

1. CNC Mills

CNC mills are the most common type of CNC machine. It is famous for its excellent precision and tolerance. This CNC machine features built-in tools for cutting and drilling and can be used for various functions, including drilling, tapping, cutting gears, and boring.

2. CNC Laser Cutting

A CNC laser cutting machine is designed to cut through hard materials using a highly focused laser to do the task. It offers a higher level of precision and provides better surface finishes than other CNC machines.

In addition, this type of CNC machine is famous for producing neat designs and is often used for decorative works such as sign making or engraving machine components.

3. CNC Plasma Cutting

Closely similar to CNC laser cutting machines, CNC plasma cutting machines are also used for cutting hard materials. But instead of using lasers, this machine uses a high-powered plasma torch that can reach up to 50,000 degrees Fahrenheit.

CNC plasma cutters are typically used in heavy industries like aerospace, automobiles, and construction.

4. CNC Lathes

A CNC lathe machine is essentially the opposite of CNC milling. Instead of the cutting tool moving toward the material to cut it away, the material itself is rotated as it is cut with a CNC lathe.

It features a lathe in the center that moves the material into position and is most suitable for products with flat, conical, or cylindrical shapes.

The CAD Model Designing Process

The CNC machining process starts with creating a 2D or 3D CAD design. Using Computer-aided software (CAD) software, manufacturers and designers can produce a model or render their products or components along with the necessary technical specs such as geometries and dimensions for creating the part.

Once the CAD design is completed, the designer exports it to a CNC-compatible file format such as IGES or STEP.

CNC Machines Programming Languages

CNC machines rely heavily on programming. In general, CNC machining programming codes are separated into two codes

- G-code: G-code or geometric code refers to the language used to instruct a machine to move. It determines the speed and movement of the machine’s cutting heads.

- M-code: Also known as miscellaneous code or machine code, the M-code gives all the info that a G-code overlooks. It includes instructions on program stops, tool change, or use of coolant.

Programmers need to input the correct codes to ensure that the CNC machines work correctly. Without these codes, CNC machining will be useless. Once these codes are written and loaded into a CNC machine, the code will do most of the work.

Industries That Use CNC Machining

CNC machining is beneficial for any business or industry that requires uniform parts or components production. Sectors that employ CNC machining include automotive, electrical, mining, defense, industrial machinery, agriculture, clothing, food, and beverage.

In particular, CNC machining is considered very important to engineers in industries where high precision is necessary, including robotics, the medical and healthcare sector, and the aerospace industry.

Essentially, there are no limits to who can use CNC machining. If your business needs a part made with precision or in large quantities, either for production or prototyping, CNC is the right solution for you.

Take Away

There’s no denying how CNC has made the manufacturing industry more efficient and productive. It has become the gold standard in precision manufacturing, thanks to its speed, accuracy, and faster overall production.

Ultimately, CNC machining is the most reliable option for business owners in any industry looking to produce high volumes of accurate mechanical components and parts for production or rapid prototyping